MPure™ Design for Web Help

Introduction

MPure™ Design for Web is an easy to use program for rapid prediction of performance and operating conditions of MPure™ electrodeionization stacks available from MEGA a.s. (Czechia).

Disclaimer of responsibility

Predictions generated by this program are only estimates of product performance. No guarantees are expressed or implied with respect to this program unless provided in writing by an authorized representative of MEGA a.s. (Czechia).

The author reserves the right to update the program, based on further development of the knowledge base, including changing the functionality without previous notice.

Release notes

List of desktop versions of the application:

-

Version 1.0.0.1 – January 2016

-

The first official release.

-

-

Version 1.0.1.0 – February 2016

-

The second official release.

-

-

Version 1.0.1.1 – July 2016

-

User can run just one instance of the program at once.

This avoids conflicts between several instances of the program which handle the same temporary files.

-

Added MPure™ 12 stack.

-

Fixed some issues with automatic calculation of number of stacks occuring when the product flow rate was limited by the maximum pressure drop (4 bar).

-

Some minor fixes to the algorithm of calculating the product flow rate and DC current per stack.

-

-

Version 1.1.0.0 – July 2017

-

Unique name for temporary files used by the program.

This avoids potential conflicts of the program with other applications.

-

Extended printing capabilities.

User can preview a project report prior to printing it and select a range of pages in the report to be printed.

-

Fixed error in calculation of SiO2 removal under some conditions.

-

Improved and optimized algorithm of calculating the product flow rate and DC current per stack (automated calculation of number of stacks).

-

Updated feed water pressure requirements.

-

Extended comments generated by the system.

-

Product quality requirements exceeding the feed water composition are not reported as mistakes.

-

User can select the decimal separator (comma or dot).

-

Updated printed reports.

-

Updated EULA.

-

-

Version 1.2.0.0 – August 2018

-

TDS can be entered and displayed in ppm or ppm as CaCO3 units.

-

Equivalent concentration (normality) such as TEC, TEA or hardness can be entered and displayed in meq/l or ppm as CaCO3 units.

-

A limit of 1 ppm of boron in the feed water has been introduced for MPure™ series stacks.

-

Target product conductivity/resistivity need not to be considered in the projection, if a target concentration of at least one component has been specified.

-

Fixed error associated with reporting input errors for the specification of the product composition.

-

User can specify the concentrate and electrode flow rates.

-

User can specify the minimum product outlet pressure.

-

An overview of the main technical and operational parameters for the selected stack is displayed in the System specification page.

-

New items have been introduced in the Settings dialog.

-

Projection can be completed even if the feed water hardness limit is exceeded. An associated notification is displayed in the System comments text box in the Comments page.

-

Improved and optimized algorithm of calculating the product flow rate and DC current per stack (automated calculation of number of stacks).

-

Fixed error associated with the DC current limit specification.

-

Fixed error in calculation of voltage that occured under some conditions (the voltage was allowed to exceed the specification limit for MPure™ stacks).

-

Fixed error in calculation of the feed water pressure that occured under some conditions.

-

Extended comments generated by the system.

-

Updated printed reports.

-

Updated EULA.

-

-

Version 1.3.1.0 – June 2019

-

Fixed some minor bugs relating to the GUI and its behaviour.

-

Fixed bug associated with an exception raised on an attempt to save a project file (when creating a new project or opening an existing project file) that was previously deleted or to which access was lost.

-

Improved performance of the program.

-

User can dynamically add one or more conditions for the target product composition. Each condition is represented by a target concentration or sum of concentrations of any ions except H+ and OH- in the product water.

-

Added MPure™ 12 stack image.

-

Updated overview of the main technical and operational parameters for the selected stack is displayed in the System specification page.

-

The Total flow rate and Total flow rate per stack text boxes have been added to the Hydraulic conditions group box in the System specification page.

-

The program predicts boron removal.

-

An effective charge of CO2 forms is correctly displayed with the negative sign.

-

Predicted pressures and pressure drops are constant at temperatures above 25 °C (77 °F).

-

A new format of a project file has been introduced.

-

Extended comments generated by the system.

-

Updated printed reports.

-

Updated help.

-

Updated EULA.

-

-

Version 1.3.2.0 – May 2020

-

Fixed some minor bugs.

-

Added bromide ions.

-

Concentrations of all conjugate forms of a component such as CO2, HCO3- and CO32- can be entered manually regardless of the dissociation equilibria.

-

Updated system comments.

-

Possibility to copy the product composition to the feed.

-

The Remove buttons in the panels representing the product composition replaced with the ✖ buttons.

-

Replaced MPure™ stack series images.

-

Application's main form is resizable.

-

Font size in the application's main form can be changed.

-

A new format of a project file has been introduced.

-

Updated help.

-

Updated EULA.

-

List of versions of the application for web:

-

Version 1.0.0.0 – February 2023

-

The first release of MPure™ Design for Web.

Desktop versions of the program discontinued.

-

Function based on the desktop version 1.3.2.0.

-

The format of the project reports changed from PDF to multi-page TIFF.

-

Changes to UI.

-

Removed the Calculate button.

-

Removed user comments.

-

Creating a project

Creating a new project

-

Select the New item from the File menu.

You might be prompted to save your previous work.

-

Fill the forms in the following pages:

-

Check the calculated operating parameters and product quality in the Results page.

-

Check the automatically generated comments in the Comments page.

-

Select the Download project file item from the File menu to download a project file.

-

Select the Download project report (*.tiff) item from the File menu to download a project report. The project report is downloaded in the multi-page TIFF file format.

-

Select the Download project report (*.xlsx) item from the File menu to download a project report. The project report is downloaded in the Excel file format.

Notes:

-

The current version of the web application does not implement state management. Reloading the website, navigating out from the website, navigating to the account management section of the website (routes beginning with https://mpure.mega.cz/Account/), longer inactivity or an unhandled exception will result in complete loss of data in all cases. Unhandled exceptions may occur due to specification of a number out of the range of its data type or due to computational errors.

-

Input errors are reported via messages at the bottom part of the website.

-

No specific file type is associated with the program.

-

It is recommended to save the project files with the *.dat extension.

-

The project files are saved in a binary format that cannot be edited in another program.

-

If the program reports input errors, no calculation will be performed. In addition, it will not be possible to download a project report.

Opening an existing project

-

Click the Choose File button.

The Open file dialog will appear.

-

Browse for the project file you want to open, select the file and then press the Open button.

-

Click the Upload button.

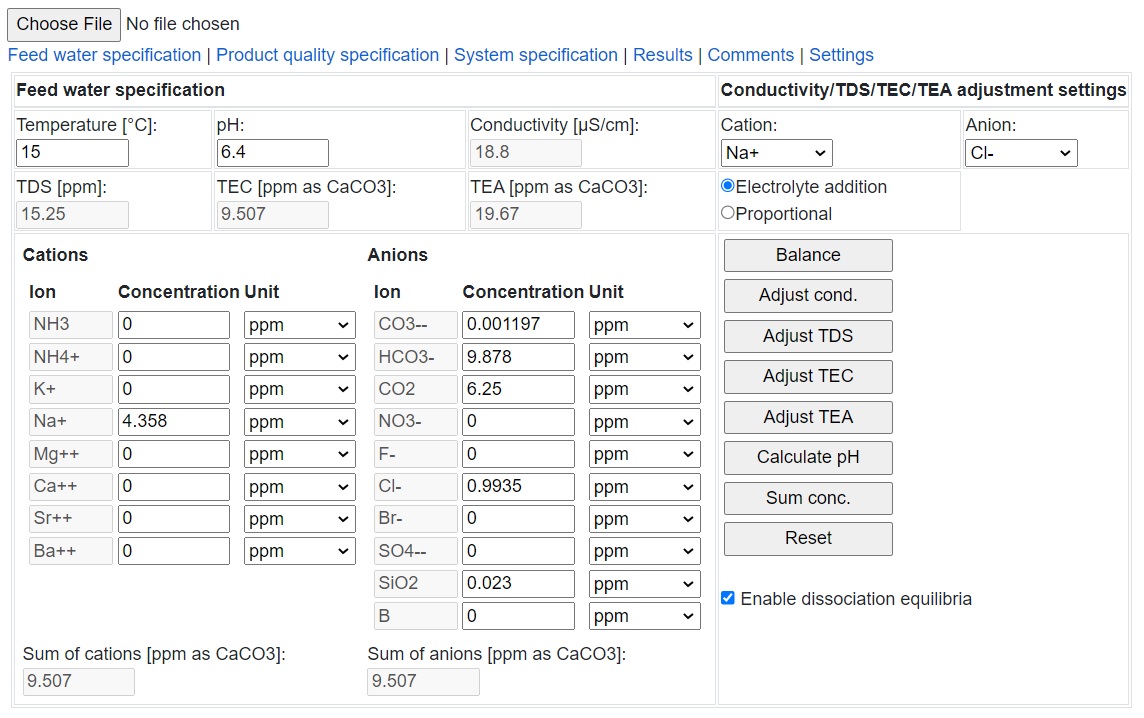

Feed water specification

-

Select the Feed water specification page.

-

Enter the feed water temperature in the given unit in the Temperature text box.

-

Enter the feed water pH in the pH text box.

-

Check the Enable dissociation equilibria check box if you want the program to support dissociation equilibria in the feed water. If it is checked, concentration of only one of the conjugate forms or the sum of concentrations of all conjugate forms of a component can be entered for systems of conjugate acids and bases such as NH4+ and NH3 or CO2, HCO3- and CO32-. Equilibrium concentrations of other conjugate forms are then calculated automatically. If you want to enter the concentrations of all conjugate forms manually, simply uncheck the Enable dissociation equilibria check box. Water dissociation is always considered regardless of the setting of the check box.

-

In the Unit columns of the Cations and Anions tables, select the unit of concentration for each component, whose concentration in the feed water you are going to enter.

-

Enter the concentration of components in the feed water in the selected unit into the Concentration columns of the Cations and Anions tables.

The program also offers several useful tools to modify or change the composition of the feed water:

-

The Balance button ensures the electric neutrality of the feed water by adding either a cation or an anion from the selected model electrolyte, see the Adjust cond./TDS/TEC/TEA button.

-

The Adjust cond./TDS/TEC/TEA button sets the conductivity/TDS/TEC/TEA of the feed water to the desired value by adding electrolyte selected in the Conductivity/TDS/TEC/TEA adjustment settings group box into the feed water (the Electrolyte addition item is checked) or by proportionally increasing the concentration of all components in the feed water (the Proportional item is checked).

-

The Calculate pH button ensures the electric neutrality of the feed water by changing its pH.

-

The Sum conc. button converts the concentrations of components in the feed water into the sums of concentrations of all their conjugate forms. Press the button if you want to preserve the sum of concentrations of all conjugate forms of the component, such as before changing the feed water pH.

-

The Reset button sets the concentration of all components in the feed water to zero and sets the default temperature and pH. After pressing this button, the feed water composition corresponds to the pure water at a temperature of 25 °C.

Notes:

-

The chemistry of water used in the program holds for aqueous solutions with a very low ionic strength only.

-

If you have entered the concentrations of conjugated forms of a component manually and then check the Enable dissociation equilibria check box, the program will first convert the concentrations of components in the feed water into the sums of concentrations of all their conjugate forms and then apply dissociation equilibrium conditions.

-

If the concentration unit is changed, the concentration will be automatically converted into the new unit.

Product quality specification

-

Select the Product quality specification page.

-

In the Product conductivity/resistivity group box, select the right option button to specify the type of conductivity/resistivity you are going to enter.

-

Enter the target (cation) conductivity/resistivity into the respective text box in the Product conductivity/resistivity group box.

-

You can dynamically add one or more conditions for the product composition to the project. To do so, select the Add condition item from the Tools menu. This will add a new panel with a few controls on it into the Product composition group box. Select an ion or another parameter such as TDS from the Ions/parameters drop-down list and then click the (+) button to add the item into the Selected ions/parameters list box. You can add one or more ions/parameters into the list in this way. If you want to remove a certain ion or parameter from the list, just select it in the Selected ions/parameters list box and then click the (-) button. Enter the target sum of concentrations of ions and parameters listed in the Selected ions/parameters list box into the Sum of concentrations text box. Select the appropriate unit of concentration from the Unit drop-down list. The ppb unit represents a mass concentration, the μmol/l unit represents a molar concentration and the ppb as CaCO3 and μeq/l units represent an equivalent concentration (normality). The condition is ignored by the program if the Selected ions/parameters list box is empty or if the check box in the given condition is unchecked. If you want to remove the condition from the project, click the ✖ button.

Notes:

-

The cation (acid) conductivity/resistivity is a measure of water quality frequently used in the power generation industry.

It expresses the conductivity of the water that has passed through a column filled with a strong cation-exchange resin in the H+ form. -

If you have correctly specified at least one condition for the product composition and you don't want to consider the target conductivity/resistivity in the projection, you can uncheck the Consider product conductivity/resistivity check box.

System specification

-

Select the System specification page.

-

In the System specification group box, select the stack series and type from the respective drop-down lists.

-

If you want to enter the number of stacks manually, uncheck the Calculate number of stacks box in the Calculation basis group box and enter the number of stacks into the Number of stacks text box in the System specification group box.

If you want the program to determine the number of stacks, check the Calculate number of stacks box in the Calculation basis group box. This will disable the Number of stacks text box in the System specification group box. -

In the Hydraulic conditions group box, enter the total product flow rate in the given unit into the Product flow rate text box.

-

In the Hydraulic conditions group box, optionally enter the total concentrate flow rate in the given unit into the Concentrate flow rate text box.

-

In the Hydraulic conditions group box, optionally enter the total electrode outlet flow rate in the given unit into the Electrode flow rate text box.

-

In the Hydraulic conditions group box, optionally enter the minimum product outlet pressure in the given unit into the Minimum product outlet pressure text box.

-

To specify operation in the countercurrent mode, check the Operation in countercurrent mode box in the Hydraulic conditions group box. Otherwise (for the co-current operation) leave the box unchecked.

Notes:

-

The program will automatically correct the concentrate and electrode flow rates either to the minimum or the maximum limits under the given conditions if values outside these ranges are set in the respective text boxes.

-

If the feed water flow rate is known instead of the product flow rate, iteratively subtract the concentrate and electrode flow rates from the target feed flow rate and set the result into the Product flow rate text box until the result is constant. For the maximum water recovery, set the concentrate and electrode flow rates to 0 after each iteration and let the program correct these values.

-

The concentrate may flow through MPure™ stacks in either the co-current or the countercurrent direction to the dilute flow. Operation in the countercurrent mode increases the feed water hardness tolerance and reduces the frequency of chemical cleaning, but it may also have negative impact on demineralization performance of the stack, especially on silica and boron removal. Operation of the concentrate in the countercurrent mode is recommended in case the feed water hardness is greater than 0.1 ppm as CaCO3.

Results

-

Select the Results page to view the results.

Comments

-

Select the Comments page to view the comments automatically generated by the program.

Settings

-

Select the Settings page.

-

Select the desired options for the physical units and other settings from the available drop-down lists or other controls.

-

The recommended DC current limit is 75 %. A lower DC current limit increases the number of EDI stacks needed, thus increases the investment costs, but provides better design margin. A higher DC current limit reduces the number of EDI stacks needed, thus reduces the investment costs, but provides worse design margin.